| Industry Overview

IVD, which stands for ln Vitro Diagnostics, refers to products that conduct testing on samples taken from the human body (such as blood, body fluids, and tissues) outside ofthe body in order to obtain clinical diagnostic information. The lVD industry is subdivided into various sectors includingimmunodiagnostics, clinical chemistry molecular diagnostics, microbiology diagnostics, blood diagnostics, and point-of-care testing(POCT).

| TOPSFLO Pump Solution

Micro pumps are a crucial driving component for in vitro diagnostic analysis. They serve as the powerelements of fluidic systems and are extensively used in various fields such as clinical chemistry, blood analysis, immunology, microbiology, etc. Micro pumps perform essential functions including sample delivery, waste removal, pipeline and component cleaning

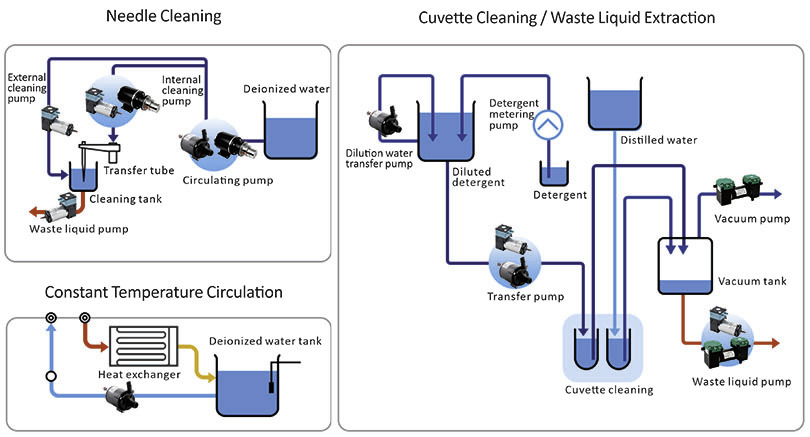

Taking the Fully Automated Biochemistry Analyzer as an example, TOPSFLO micro pump can be used in systems such as needle cleaning, cuvette washing, and constant temperature circulation:

—Diaphragm Liquid Pump

Diaphragm pumps are the most widely used pumps in lVD instruments, especiallyin waste systems, where theyclean and eliminate waste from reaction cups and pipelines. In this process, diaphragm liquid pumps can directly pump out waste liquids

Alternativelv, miniature vacuum pumps can be used to create a vacuum in sealed containers, indirectly drawing out waste from he instrument, This method is effcient and the waste doesn’t pas through the pump chamber thus extending the pump’s lifespan.

Depending on the specific application, there are larger double-headed and single-headed vacuum pumps used to create a vacuum in containers, as wellas smaller diaphragm pumps with lower flow rates and pressures. Small diaphragm pumps are often emploved to directlvextract waste from individual needle. Miniature pumps need to operate under various working pressures,meeting the demands of different pressure and flow scenarios.

Zero Cross-Contamination

Providinga clean environment for the transfer,extraction, and compression of gases; oil-free and maintenance-free

High Air-tightness

Highly airtight diaphragm pumps are crucial for lVD equipment becausethey ensure the precision,reliability, and repeatability of tests thus supporting accurate diagnostics and analysis.

Precise Flow Rate

IVD systems rely on highly reliable sample introduction systems to complete processes such as sample pretreatment, sample/reagent addition, and more.lt’s crucial to ensure the high-precision and high-repeatability conveyance of samples and reagents, along with maintaining smooth flowand minimal pulsation in the process.

TF Series Specificactions

Flow Max:3L/min (0.8 GPM)

Water Head: ≥10m (1Bar)

Ambient Temperature: -20~60℃

Media temperature: -5~60℃

LifeTime: 15000 Hours

—Diaphragm Gas Pump

Corrosion Resistance

When flushing pipelines and needles, corrosive solvents are often used, and it’s necessary to promptly remove waste containing crystals or blood clots from the system. Therefore miniature pumps need to possess a certain level ofcorrosion resistance. The pump head,diaphragm, and valve components of TOPSFLO diaphragm pumps can all be customized with a variety ofmaterials to accommodate different solvents.

Extremely Long Product Lifespan

Within the lifecycle of IVD instruments, there is a requirementfor miniature pumps to not require replacement, to have a long operational lifespan,and to maintain stability and reliability.

Compact Structure, Flexible Installation

IVD systems typically need to accommodate other criticalcomponents such as sensors, valves, and reservoirs. With limited space for equipment and components, there is a requirement for miniature pumps to have a compact structure and flexible installation capabilities.

TM Series Specifications

Flow Max: 17L/min (4.50 US GPM)

Max pressure:220Kpa

Max vacuum:95Kpa

Ambient Temperature: -20~60℃

Media temperature: -5~60℃

Life Time:15000 Hours

—Centrifugal Pump

TOPSFLO centrifugal pumps are commonly used in lVD to regulate the temperature ofin vitro diagnostic reagent kits. enzyme-inked immunosorbent assav (ELISA) instruments, fuorescence analvzers,and more.This ensures the accuracyand reproducibility ofexperiments.

The following are the requirements for pumps in the IVD circulation constant temperature system:

Reliability and Stability

The lVD equipment demands highly reliable results, requiring centrifugal pumps to exhibit high stability to ensure continuous operation without any failures. Furthermore, within the IVD instrument’s lifespan of 10 to 15 years, it is expectedthat the micro pumps do not require replacement.

TOPSFLO pumps have successfully passed reliabilityvalidation from major IVD manufacturers demonstrating a long lifespan and stable reliability.

Zero Cross-Contamination

In the IVD system, cross-contamination can lead to errors andinaccurate results. For instance,deionized water within the system needs to possess high purity to ensure that the flowing water does not contaminate samples or reagents.Additionally, the pump itself must avoid releasing even trace amounts ofpollutants

TOPSFLO pumps utilize food-grade materials achieving genuine zero impurities and zero cross-contamination.This approach contributes to medical equipment providing the most authentic and reliable test data.

Corrosion Resistance

Alkaline cleaning solutions possess a certain leve of corrosiveness, requiring pumps to be corrosion-resistantto prevent damage during the handling process

TOPSFLO adopts corrosion-resistant materials and has successfully passed alkaline cleaning solution immersion tests conducted byvarious major IVD manufacturers.

TL Series Specifications

Flow Max: 24L/min (6.34 US GPM)

Water Head: 35M

Ambient Temperature: -40~40℃

Media temperature: -40~105℃

IP Rate: IP68

—Gear Pump

Gear pumps are commonly used for cleaning the inner walls of needles with high pipe resistance. The cleaning effectiveness of the needleis closelyrelated to the interna roughness and design ofthe inner needle wa, but more importantly, it’s correlatec with the high pressure provided by the gear pump.High-pressure flushing of the inner walls ensures an adequate cleaning flow even under high resistance conditions.

Stable pressure output

Gear pumps should be capable of providing a stable pressure output to ensure the flushing force of liquids within the system.

Reliability and Stability

IVD equipment typically requires precise flow control to ensure accurate dosing, mixing, and transfer of reagents, samples, or other liquids. TOPSFLO gear pumps possess stable flow control capabilities to meet experimental requirements.

Corrosion resistance

IVD equipment may use various types of reagents and samples, some of which might be corrosive.The materials of TOPSFLO gear pumps are designea to withstand the characteristics ofthe liquids used to prevent pump damage during operation.

Reliability and Durability

Gear pumps need to have high reliability, capable of continuous operation over extended periods and maintaining performance stability throughout the equipment’s entire lifespan.

MG Series Specifications

Flow Max: 6.5L/min (1.72 USGPM)

Max Output Pressure: 10bar (145.04 psi)

Max System Pressure: 20 Bar (290.08 psi)

Ambient Temperature: -30~50℃

Media temperature: -10~100℃

Reputación y experiencia reales. Ayudar a empresas de clase mundial a mejorar la competitividad central de sus productos.